How Do Inverters Convert DC to AC? Everything You Need to Know

28th August 2024Share This Post

Share This Post

Picture this: you’re in the middle of a power outage, yet your backup system seamlessly takes over, keeping the lights on and essential devices running. How does this happen? The answer lies in a device called an inverter. These clever pieces of equipment are responsible for converting stored DC (direct current) power from batteries into AC (alternating current) power that most of our applications rely on. In this blog, we’ll explore how inverters achieve this transformation and why they’re crucial across various industries, from renewable energy setups to railway systems.

The Science Behind Inverters: Turning DC into AC

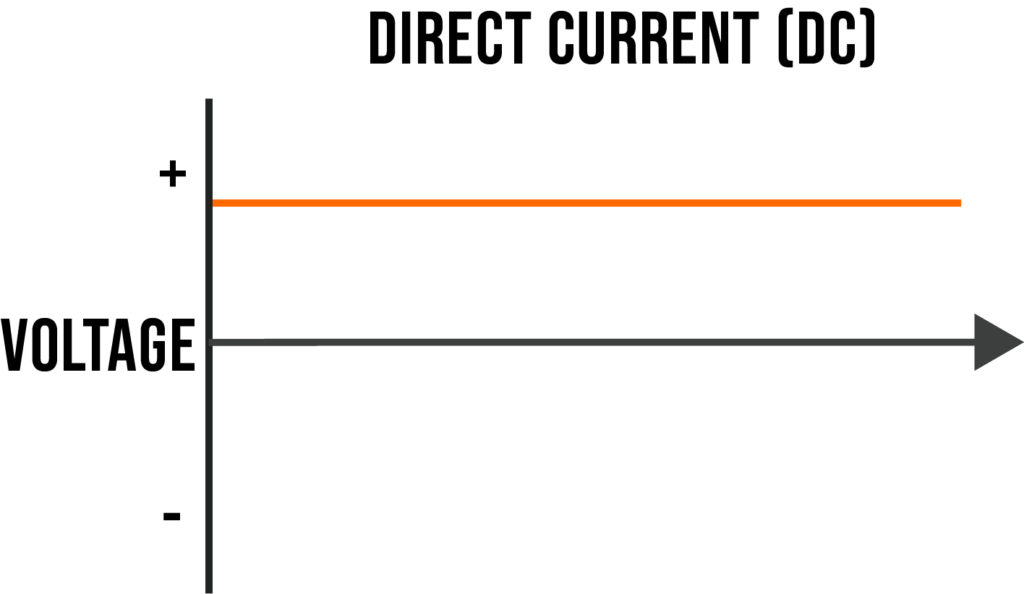

To grasp the role of inverters, let’s start with a quick overview of electrical currents. DC, or direct current, flows steadily in a single direction, making it ideal for storing energy in batteries. On the other hand, AC, or alternating current, constantly changes direction, making it the preferred format for most household appliances and industrial machines. The job of an inverter is to transform the stable flow of DC into the oscillating pattern of AC. But how exactly does it manage this?

At the heart of the inverter are switching components. These components alternate the direction of the current at a rapid pace matching the frequency of your local power grid such as 50Hz or 60Hz. The switching process creates an AC waveform, allowing your equipment to run smoothly as if it were connected directly to the grid. Sounds but not when you consider the types of inverters and their real-world applications.

Types of Inverters and How They Work

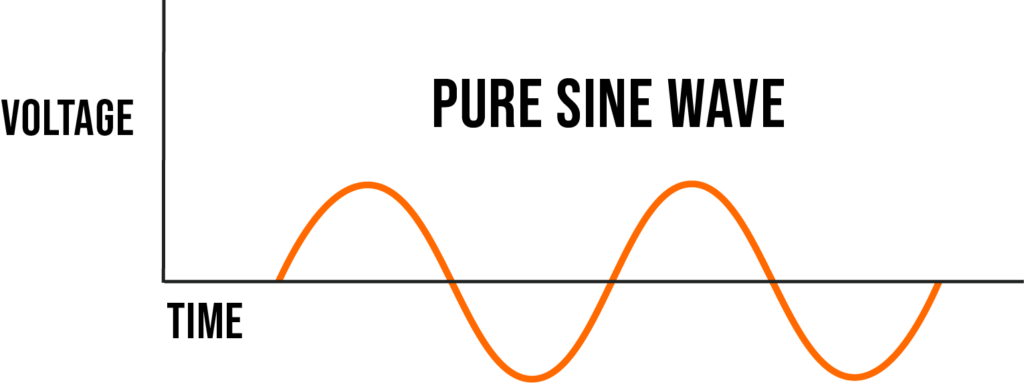

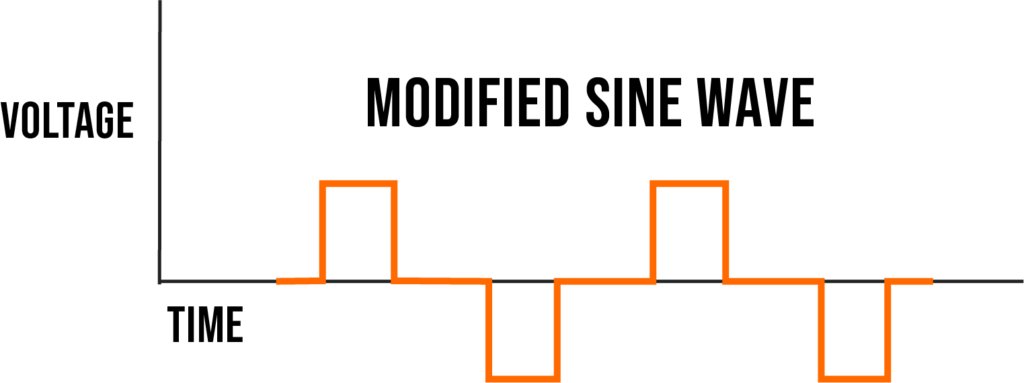

Inverters generally fall into two categories: pure sine wave and modified sine wave.

These produce a smooth, clean sine wave that mirrors the quality of the grid’s AC supply. They’re ideal for sensitive electronics, medical devices, and equipment requiring consistent, high-quality power.

These produce a step-like waveform, which is simpler and cheaper to generate but can cause issues with more sensitive devices. They’re often found in less demanding applications like powering basic appliances or tools.

Regardless of the type, all inverters rely on pulse width modulation (PWM) to control the width and timing of the electrical pulses, generating a stable AC output. The benefits of modern inverters include high efficiency, reduced heat loss, and even remote monitoring features for certain models.

Key Applications: Where DC to AC Conversion Matters Most

Inverters are essential in today’s industrial landscape, playing vital roles across numerous industries. Here are some of the primary applications:

Uninterruptible Power Supplies

Energy

Electric Vehicles

Railway Systems

The Evolution of Inverters – SiC and GaN Technology

In recent years, significant advancements have been made in the efficiency and power density of inverters, largely due to the introduction of Silicon Carbide (SiC) and Gallium Nitride (GaN) transistors. These materials offer superior performance compared to traditional silicon-based components. SiC and GaN devices allow inverters to operate at higher switching frequencies, leading to smaller, lighter, and more efficient designs. This is particularly important in applications where space and efficiency are critical, such as electric vehicles and renewable energy systems.

Silicon Carbide inverters have gained traction due to their ability to handle higher voltages and temperatures, making them ideal for heavy-duty industrial and automotive applications. The reduced switching losses mean more energy is converted to usable power, minimising heat generation.

Gallium Nitride transistors are known for their high-speed switching and efficiency at lower voltages. This makes them a preferred choice in consumer electronics, compact power supplies, and even 5G systems. As GaN technology becomes more mainstream, it’s driving innovation in more compact and efficient inverters.

The adoption of these advanced materials is setting new standards in power conversion, pushing the boundaries of what’s possible in terms of size, performance, and cost-effectiveness.

The Future of Inverters: Smarter, Smaller, Stronger

As demand grows for reliable, clean energy solutions, inverters are evolving. From integrating more seamlessly with smart grids to improving their performance in renewable energy setups, the future looks bright. We can expect smaller, more powerful inverters capable of handling higher loads while offering advanced monitoring and control features. With the rise of electric vehicles and renewable energy, these devices will only become more critical in powering our world.

Our DC-AC inverter range

In Summary

Inverters are the backbone of countless projects, transforming simple DC into the AC that keeps our world spinning. Whether it’s maintaining uninterrupted power in a hospital or driving your solar-powered home, inverters are pivotal to efficiency and reliability. As advancements continue, these devices will play an even bigger role in energy management, sustainability, and everyday convenience.

Need help choosing the right inverter for your application?

Contact our expert team today for tailored advice and solutions that meet your exact needs. Let’s start a conversation today!

SHARE

sign up for our newsletter

Enter your email address below

LET’S MAKE THIS EASY. CALL 01929 555 700

why choose relec?

-

Faster

Our aim is to get back to you with an initial response within the hour.

-

Attention to detail

We pride ourselves on getting you the right product, at the right price and on time.

-

New ideas

We are constantly looking for latest technology and products for your applications.

-

Beyond standard

It’s not just about the product. Our service goes way beyond the norm.

-

Easy

We want to make your life as simple as it can be. Call us to find out what we can offer.