EN61000-4-2 Dissected: No Shocks When It Comes to ESD

16th May 2023Share This Post

Share This Post

Introduction

Placing any product on the open market requires a certain level of compliance testing. With regards to electronic and electrical systems the key ones that apply will be safety (EN62368-1, EN61010 or EN60335 for example) and EMC (Electromagnetic compatibility) requirements. Over the next few articles, we are going to take a deeper look into some of these EMC standards, in particular the area of EMC immunity (The ability to withstand and continue to function properly when exposed to electromagnetic interference (EMI) which comes from other electronic devices or electromagnetic fields in the environment).

Overview

EMI can come from a variety of sources including electrical, magnetic, RF as well as those caused by variations in the incoming supply. Immunity to these effects is typically measured through are series of standardized tests, which evaluate the device’s ability to resist EMI at different frequencies and power levels. These tests are covered under the EN61000 series and involve exposing the device under test to EMI at defined levels whilst monitoring its performance to determine if it meets the required performance criteria. The results of these tests are classified in terms of the loss of function or degradation of performance of the equipment as follows:

Performance Criteria

A) Normal performance within limits specified by the manufacturer. This can vary but we are going to use the limits specified within the Melcher range of products for this exercise. Melcher specifies normal performance as the output voltage of a power supply not deviating by more than 3% from the value prior to the test.

B) Temporary loss of function or degradation of performance which ceases after the disturbance ceases. Melcher specifies degradation of performance as a voltage deviation of more than 3% from the value before the test.

C) Temporary loss of function or degradation of performance, the correction of which requires operator intervention or system reset. In case of Melcher power supplies, operator intervention can mean turning the unit off and on by removal and reapplication of the input supply or by means of the inhibit input.

D) Loss of function or degradation of performance which is not recoverable, due to damage of hardware or software or loss of data. This is fairly straightforward. The unit under test has failed to operate and will not restart.

EN61000 series overview

We are going to focus here on part 4 of the EN61000 series. Parts 1 & 2 cover the general methodology and environment for testing and part 3 looks at harmonic currents, which we covered in an earlier article. Part 4 is where things start to get interesting, which specific tests designed to ascertain if equipment is protected against different EMC disturbances.

It is important to highlight here, that compliance of a system component (i.e a power supply or display in our case) to a particular standard, does not equate to the final system being guaranteed to also be compliant. Whilst many of the tests detailed will be directed the power inputs of a system, it is still feasible that energy can enter a system by other means and cause a failure.

IEC/EN61000-4-2: Electrostatic discharge (ESD) immunity test

Static electricity discharges may be present in environments with a low relative humidity, typically being generated from low conductivity artificial fibres such as carpets, vinyl garments, or even something as simple as picking up a polyurethane bag. EN61000-4-2 specifies the requirements and tests for the immunity of electrical or electronic equipment which are subject to electrostatic discharge which might be generated in this way.

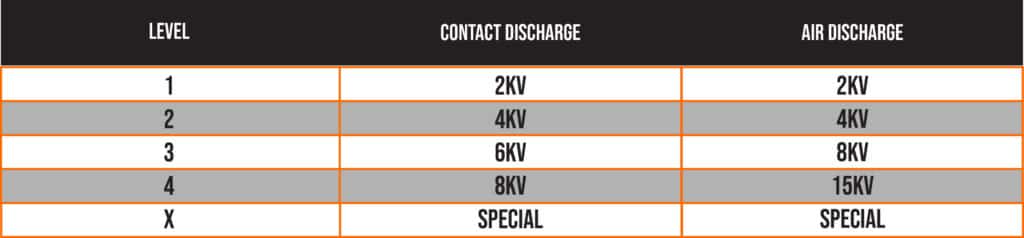

The tests themselves define 4 different test levels, which can be evaluated using 2 different test methods (Contact and air discharge). Contact discharge is the most common method, where an electrostatic discharge (ESD) gun is brought into contact with the equipment under test (EUT) and a high voltage is applied directly. Under certain circumstances this might not be possible (Some equipment might be sensitive to touch or pressure), in which case an air discharge can be made.

Test levels

The discharge levels associated with a particular type of equipment will be detailed in their own specific product standards. Typically, the following will apply:

Systems which are installed in a controlled environment and with additional anti-static precautions.

Systems which are only occasionally handled.

Systems which are continuously handled.

The tests themselves define 4 different test levels, which can be evaluated using 2 different test methods (Contact and air discharge). Contact discharge is the most common method, where an electrostatic discharge (ESD) gun is brought into contact with the equipment under test (EUT) and a high voltage is applied directly. Under certain circumstances this might not be possible (Some equipment might be sensitive to touch or pressure), in which case an air discharge can be made.

Related Content

Power Factor Correction, Harmonic Currents & EN61000-3-2, what’s the problem?

ESD Pulse Characteristics

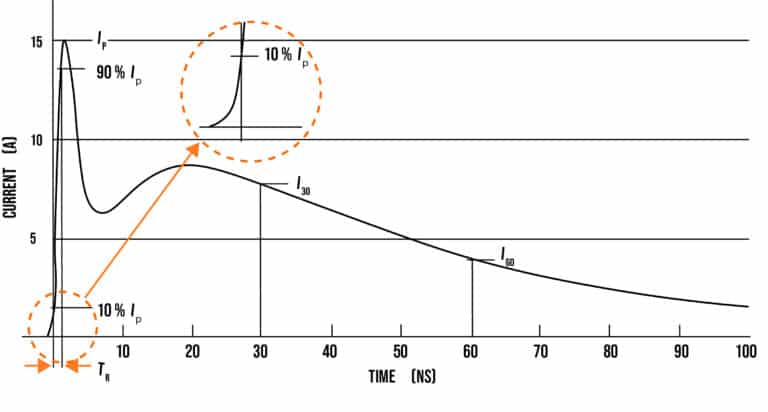

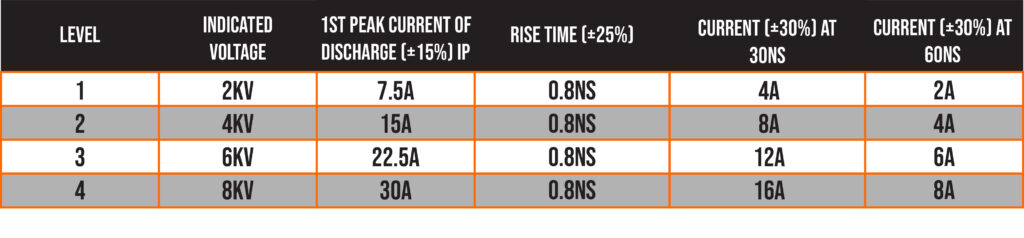

The waveform below describes the output of a typical ESD generator (or ESD gun) that is used to test compliance to EN61000-4-2. The waveform is defined by its first peak current (Ip), rise time from 10 – 90% of Ip and the current at 30 ns and 60 ns are compared with the ideal generator characteristics.

Designing for ESD immunity

There are a number of simple procedures that can be followed to ensure your equipment complies with EN61000-4-2. These include:

- Provide short electrical paths for ESD currents to system ground. These can be through the use of transient voltage suppressors or Class Y capacitors. Special care should be taken to ensure that the tracks to these devices are as short as possible.

- Inputs and outputs that can be exposed to ESD impulses should be individually protected.

- Use of metal shielding

- Having adequate track separation on PCBs

- Selection of system components (power supplies and displays for example) that have proven compliance to EN61000-4-2

RECENT articles

GET IN TOUCH TODAY – 01929 555700

Here at Relec Electronics, we have worked closely with our key suppliers for over 40 years. We specialise in many industries, including; automotive, industrial, transportation, instrumentation & defence. We have a team of dedicated engineers ready to support you throughout the design process. We also carry stock of all standard modules and accessories for next day delivery.

Let’s make this easy and call us today.

Follow us on Facebook, LinkedIn & Twitter for updates on all of the latest Power Conversion & Display products.

Sign up to our monthly newsletter below, and never miss out on our updates of industry news, we release news/blog pages weekly with news from the power and display industries.

Relec Electronics holds the highest standards towards finding you the ideal solution for your application. We truly believe “Standard is Just the Beginning”. Get in touch with our technical team today.

SHARE

sign up for our newsletter

Enter your email address below

LET’S MAKE THIS EASY. CALL 01929 555 700

why choose relec?

-

Faster

Our aim is to get back to you with an initial response within the hour.

-

Attention to detail

We pride ourselves on getting you the right product, at the right price and on time.

-

New ideas

We are constantly looking for latest technology and products for your applications.

-

Beyond standard

It’s not just about the product. Our service goes way beyond the norm.

-

Easy

We want to make your life as simple as it can be. Call us to find out what we can offer.